RELATED Labeling & Coding PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

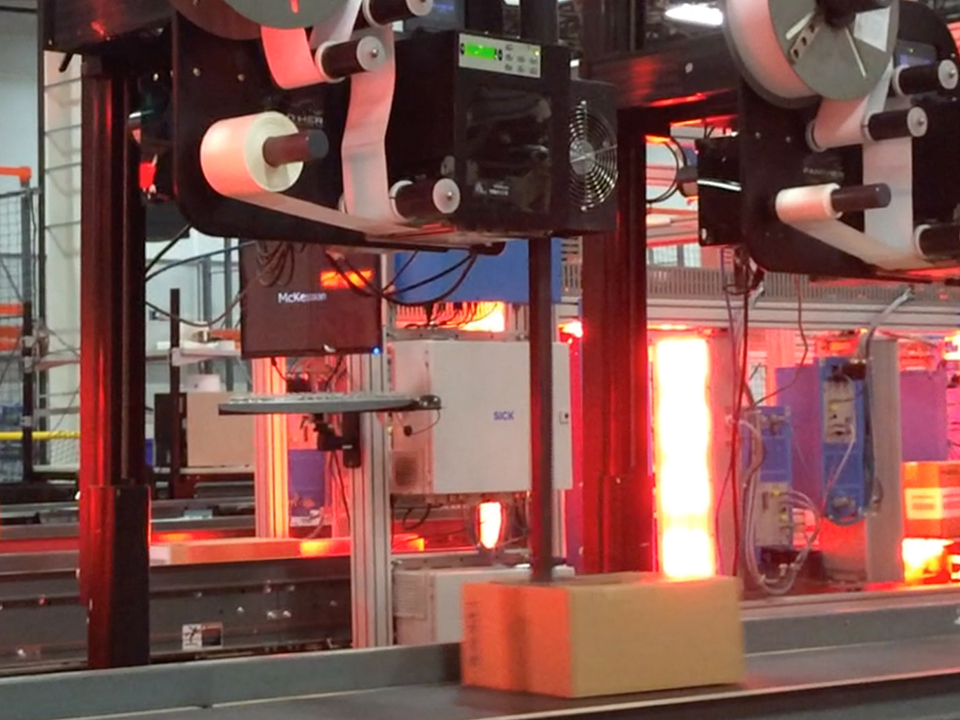

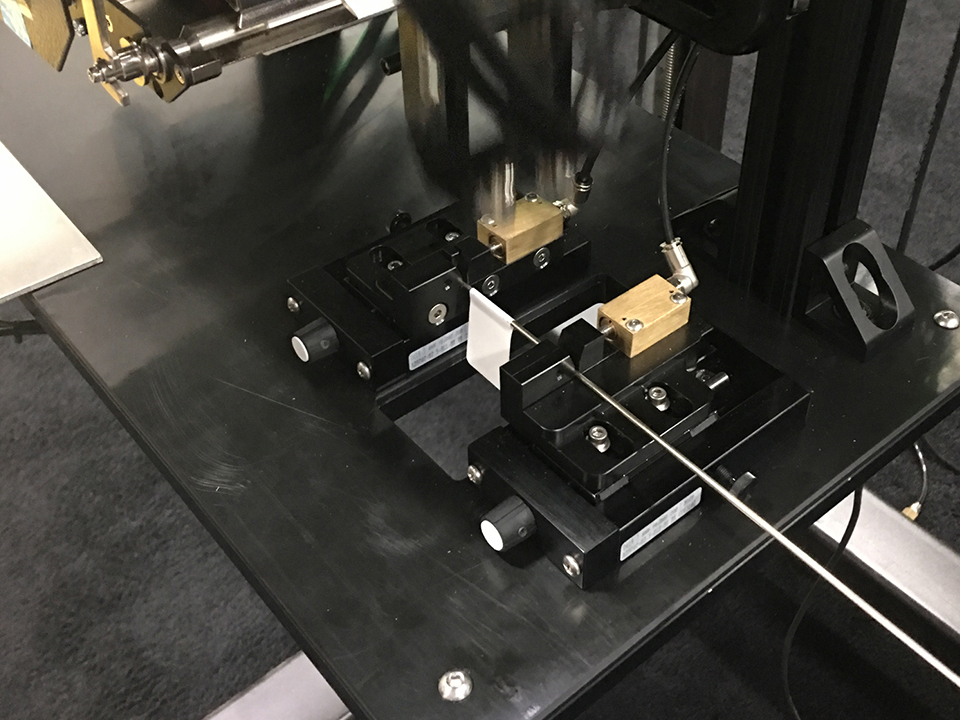

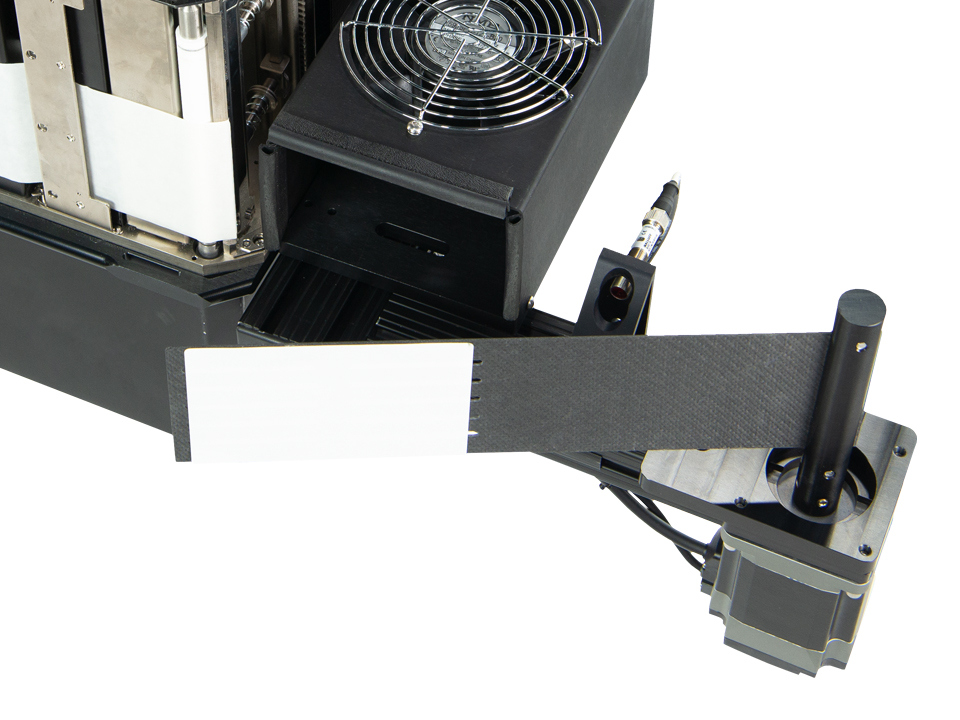

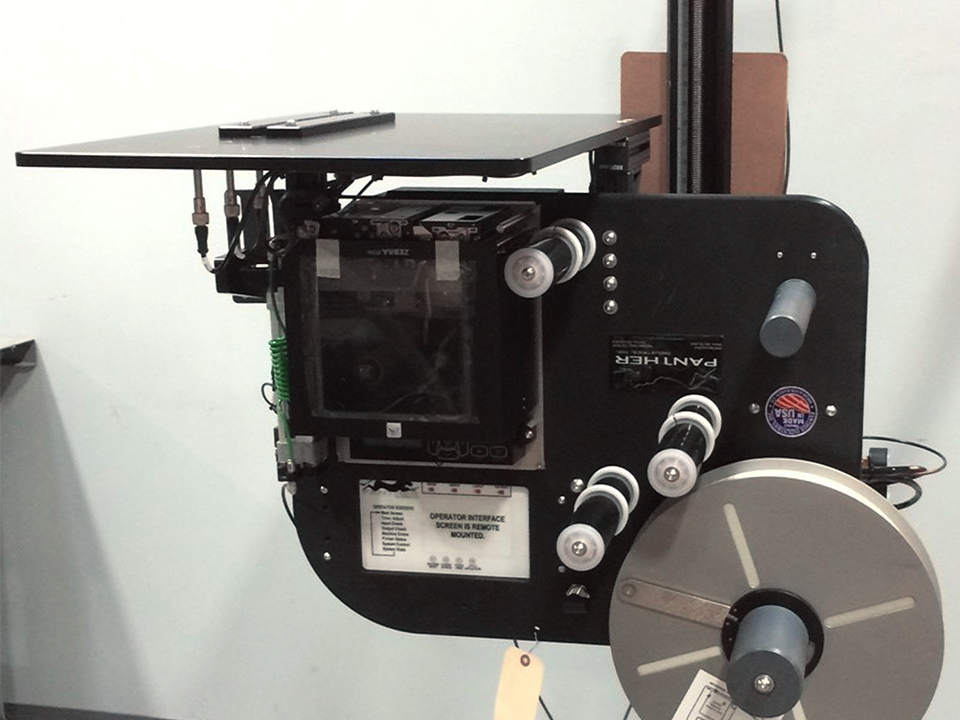

As a leading single source provider of high-quality labeling, coding, and marking systems, ProMach designs, manufactures, and integrates custom identification solutions to ensure peak operational efficiency. With advanced systems for applications in primary and secondary packaging, as well as distribution and fulfillment environments, our solutions provide accurate labeling and coding on virtually every substrate in every market.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn more